Technology Development:

• Joining methods for similar & dissimilar material combination

• Introduction and adaptation of new processes

• Mechanization & Automation of welding

• Selection of processes, consumables and techniques to reduce defects

• Solving problems related to joining of reactive and exotic materials

• Overlaying, Cladding and Hard-facing

• Micro-joining and Brazing

Power Source Testing & Evaluation

WRD can offer services to evaluate static & dynamic characteristics of arc welding power sources

using CWI-ADM Model

III. The transient arc voltage and current signals will be statistically evaluated using special software

integrated to

the system and statistical parameters like standard deviation; variation co-efficient etc. can be evaluated

in real

time.

Management Support Services

For customers desiring to set up new installation and /or modernizing the welding & fabrication

facilities, following

management support services are offered.

• Productivity and Quality Improvement through Weld & Quality audit: Covering Weld & Quality audit covering

Welding

Procedure Specification, Procedure Qualification Record, industrial practices, power sources, welding

equipments, online

monitors, welding consumables, welding personnel, storage & handling safety, quality control procedures,

etc.

• Plant Layout: Covering review of blue prints of the location of plant & machinery, selection of welding

systems,

material handling, check of vendor listing & registration, system manuals, etc.

• Manufacturing support, Retrofitting & modernization, health & safety of personnel.

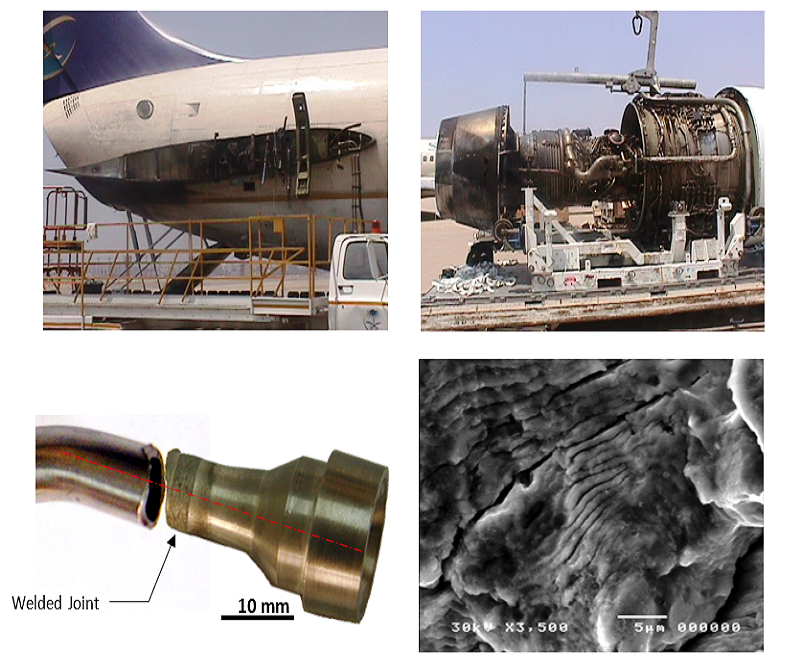

Repair & Reclamation

Assistance can be provided in rectification and repair of worn-out or cracked components,

assessment of the extent of

damage & feasibility of repair and recommendation of appropriate weld repair & reclamation procedure.

Services for

surveillance during repair at site and if necessary, the repair can also be carried out by WRD personnel.

Welding Procedure Specification

Assessment of weldability of new materials, establishment of welding procedures as per pressure

vessel, structural

welding or applicable codes such as ASME, AWS, ISO, EN, API, etc. and evolve Welding Procedure

Specification.

Residual Life Assessment of Power and Process Plants

Assessment of damage and metallurgical condition by Nondestructive Test Technique, and In-situ

metallography (Replica

test) and recommend run-retire-repair solutions.